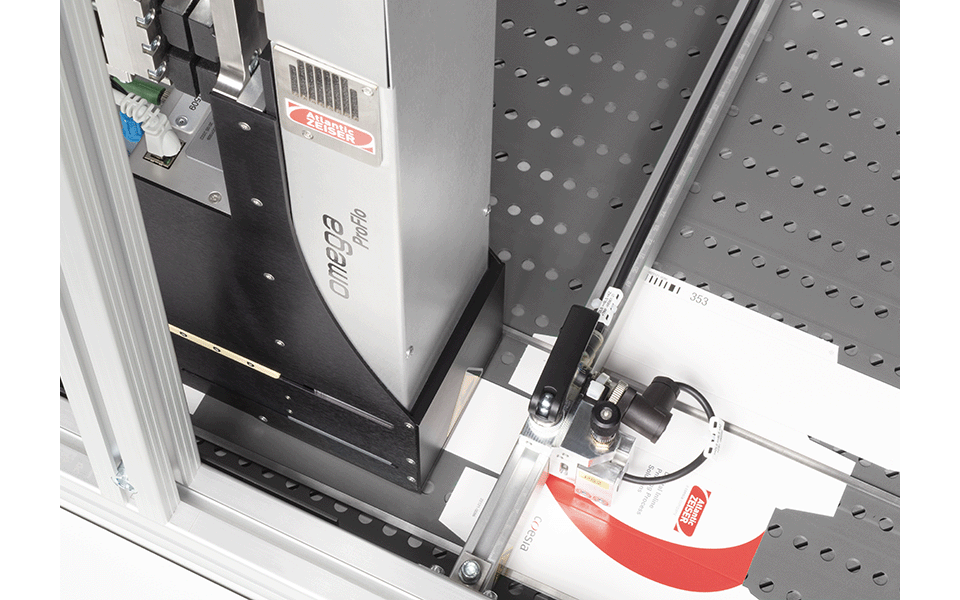

Secondary Packaging Printing

Digital printing for cardboards and rigid plastics

When digitally printing secondary packaging, DoD technology can play out three decisive advantages: its color brilliance, its speed, and the razor-sharp print image even with the smallest fonts or complex codes. In addition, the UV inks used are highly resistant to abrasion, light, and alcohol-based solvents. Printing can be carried out on the still flat cartons, or on the cartons that have already been set up and filled.