Packaging on-Demand Solutions

Customization of packaging has swept the Fast Moving Consumer Goods (FMCG) industries in recent years. It's been driven by:

- Globalization of markets

- More stringent regulatory and retailer traceability requirements

- Shorter production runs

- Increase in consumer demand for targeted, personalized products

Brand owners of consumer packaged goods want to be able to react faster to market opportunities. Specifically, they need to segment and differentiate their products to serve market micro niches. They seek agility via digital printing.

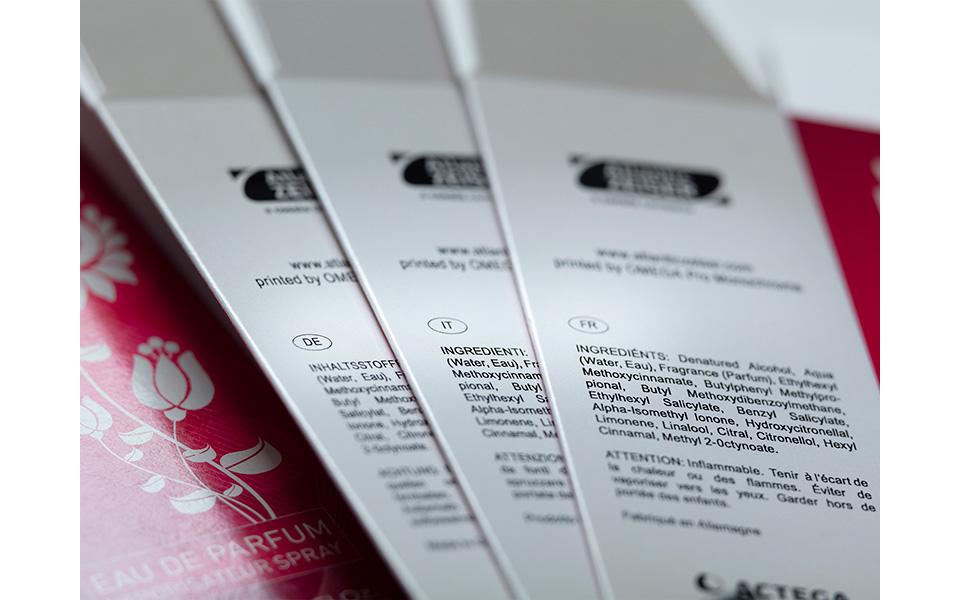

Atlantic Zeiser is the preferred partner for inline, nearline and offline digital printing solutions. Innovative drop-on-demand (DoD) printing technology enabling high-quality solutions for identification, marking, coding, product decoration, and late-stage customization of packaging.

Atlantic Zeiser develops solutions with which mass-market products can be individualized due to a reliable, cost effective, and high speed process.