Description

The digital press for flat and cut-sheet cartons

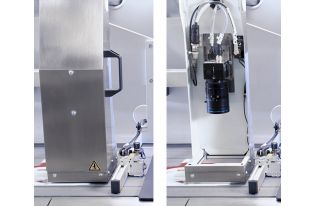

DIGILINE Single is a fully integrated, modular solution for packaging customization. The system is ideal for medium and high-volume late-stage customization of cartons, which can be pre-cut (flat or folded-glued) as well as pre-printed.

DIGILINE Single combines several state-of-the-art technologies to provide consistent high printing quality and durable long-lasting prints. DIGILINE Single can be used for different applications in the packaging sector.

The versatile transport mechanism of DIGILINE Single allows the use and retrofit of a multitude of modules like DOD UV-inkjet printers in different widths, labelers or inspection cameras. Coded products that have not been approved by the inspection camera are rejected reliably through the waste gate.

Key Benefits

- Shorten packaging design-to-delivery lead times

- Print on any or all parts within the package layout

- Reduce complexity: print on-demand, when needed

- Improve agility and flexibility: print variable data and serialization including country- or market-specific information

- Minimize waste: streamline SKU versioning and sourcing

- Save time: reduce job changeover time and artwork adjustments

- Working width up to 600 mm

- Printing width up to 161 mm

- Printing speed up to 80 m/min at 600 dpi

- Application tailored inks: monochrome black, white, high-density white, and spot colors

- ProFlo inkjet technology with ink recirculation for unprecedented uptime, jet reliability, and low maintenance

- Improved print quality and consistency – monochrome serialization and late-stage customization, or spot-color printing

- Detection of unexpected carton types and non-aligned cartons

- Double feed and product length detection

- Precise, modular and ajustable vacuum transport system

- High cost-efficiency thanks to fast change-over of jobs

- Retrofit of additional modules possible

This optional anti‑diversion package integrates seamlessly with our CodeVault serialization hub, enabling you to collaborate directly with your customers who need to implement anti‑diversion processes across their supply chains.

- Customer‑initiated code requests: your customers can assign unique serialized codes directly for your printers

- Streamlined web‑to‑print‑to‑verify workflow: covering code generation, artwork management, printing, and code verification within a single digital process

- Automated reporting & secure data handling: encrypted upload and storage of codes, with controlled access to production logs and audit trails

- Instant customer access & tracking: codes can be retrieved, activated, and monitored by your customers in real time for full transparency

Related NEWS